We keep describing ourselves at Interwoven Design as a design consultancy that specializes in soft goods and wearable technology, but what is a design consultancy, and why would you work with one in the first place? In this article we explain the many benefits of working with a design consultancy, and under what circumstances it might be the right choice for you.

What are the benefits of working with a design consultancy?

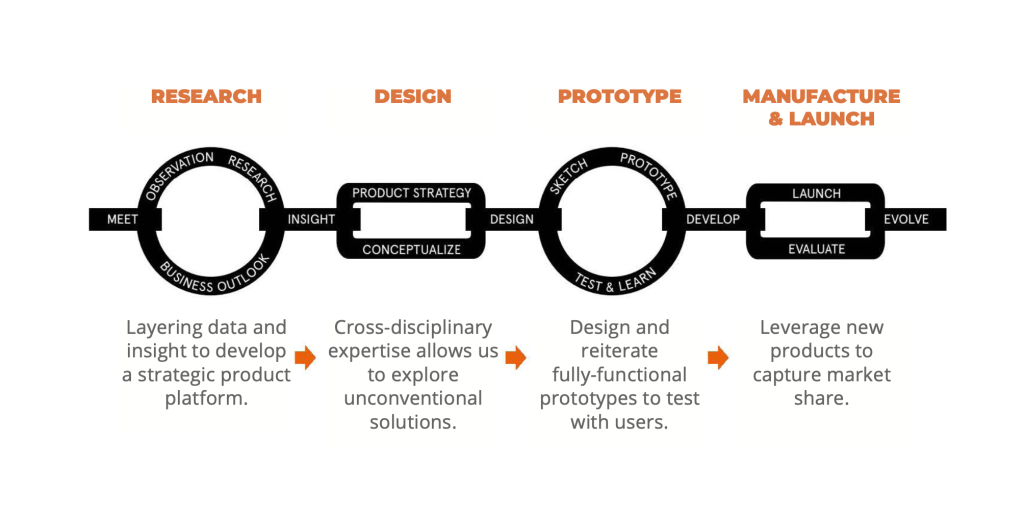

Let’s say you have an idea, and you’re interested in developing it. Regardless of how vague or refined the concept might be at the start, research and development is not a straight line. It’s a convoluted, long-term process that can take months or years to complete successfully. It takes a special combination of knowledge and skills to do efficiently and effectively, and these are completely different skills from those needed to manufacture, promote, and sell existing products. While some companies have the resources to do this on their own, it is far more likely that the development is outsourced to another kind of company, one that specializes in bringing ideas to life. This is the design consultancy.

While any given company is an expert on their slice of the market to some degree, it is less likely that they are also experts in trends, marketing, a new area of the market for their brand, ergonomics, behavioral psychology, research, testing, prototyping, and all manner of skills needed to create innovative products that can succeed. Diverse teams are more creative, and these teams need diversity not only in gender and background but in skills, experience, and knowledge, both professional and personal. Design consultancies come in a wide variety of flavors, which means that a company can identify the specific array of skills that are needed for their particular project and have access to those skills in a convenient package.

When is the right time to work with a design consultancy?

Giant corporations (think Estée Lauder or Proctor & Gamble), who need to constantly diversify and expand their own innumerable product lines—as well as those of their child corporations— are likely to have a dedicated R&D department, or even multiple R&D departments. They are generating so many products for existing and reliable distribution channels that it is logical and economical to develop projects internally. Many companies don’t need R&D at all times, they need it at specific times to accomplish specific goals for their growth and development.

Big companies known for their dedication to innovation (think Nike or Patagonia) are another kind of company that is likely to have in-house R&D. After decades of demonstrating this dedication, they have amassed a faithful audience for cutting-edge products. It is part of their branding strategy to push the envelope in their industries, and while it is of course valuable to sell the products, it is enormously valuable to be pioneers in new spaces in the market, and to develop newsworthy projects. While many companies would appreciate the branding and market benefits of innovation, they don’t have the time or the expertise to generate it.

A typical business isn’t likely to have the luxury of in-house R&D. They often don’t have the time, flexibility, funds, or bandwidth to do their own in-house development. All of their employees have tasks to complete, and those tasks cannot be suspended for a year or more to transition them to research and exploration. That said, companies still see value in developing new products for existing product lines, developing new product lines, expanding into new product categories, and offering cutting-edge products within their industries. Design consultancies are often behind new brand launches as well, and could be the right fit for a new company looking to establish their place in the market. When you want to achieve any one of these goals, it could be a good time to find a design consultancy.

To sum up

Working with a design consultancy allows small, medium, and even large companies to outsource R&D to experts who can work knowledgeable and efficiently to bring a product to the market. A company with a certain set of skills can gain access to an entirely distinct and targeted set of skills without needing to headhunt and hire for them. This saves time and money. You get a team with precisely the skills you need when you need them in a convenient bundle, a team that is professionally trained to innovate and develop ideas on a timeline, within a budget. Are you curious about industrial design and product development? Sign up for our newsletter and follow us on Instagram and LinkedIn for design news, multi-media recommendations, and to learn more about product design and development!