What is Soft Goods Design?

Interwoven specializes in soft goods design but… what are soft goods, anyway? And what is soft goods design? We’ll walk you through how to define and identify soft goods and some of the important design considerations behind our favorite products to make.

So…what are soft goods?

Soft goods are a growing market in the US, with influencing factors that include the rise of homeownership and the general rise in consumption witnessed since 2020. The largest market players are driven by innovation (that’s us!), eco-friendly business practices (that’s us, too!), and product line expansion (we do that!).

The dictionary definition of soft goods is:

“goods that are not durable —used especially of textile products”

~ Merriam-Webster

The term was first used in 1798 during the industrial revolution. Soft goods are primarily made with soft, non-rigid materials, though rigid materials can be incorporated into the design as well. Their characteristics tend to include comfort, cushioning or impact resistance, wearability, ergonomics, and aesthetic appeal. Think of your most beautiful and treasured belongings: how many of them are soft?

The materials that make up soft goods include not only textiles but paper, foam, rubber, gels, and other yielding or flexible materials. While they may last for decades, they are still understood as having a limited lifespan due to the gradual wear and tear on the non-rigid material components.

If this definition may seem broad and somewhat vague, that’s because it is. The open description reflects that soft goods are a large category, encompassing a wide range of products. Some people think first of functional apparel when they think of soft goods but this is not the primary usage in the industry. Many soft goods incorporate solid or plastic components like backpacks, bags, tents and other sporting equipment, and medical devices. The easy way to think about it is that soft goods are made primarily with ‘soft’ materials, but it’s only useful once you’ve understood the deeper definition.

Wait, what are soft goods not?

While soft goods have some overlap with non-durable consumable goods, they are not quite interchangeable terms. Non-durable goods are considered those purchased for immediate or near-immediate consumption with a lifespan of three years or less. These include household goods like laundry detergent and sponges, apparel, shoes, cosmetics, and gasoline. Compare these with durable consumer goods, which include things like vehicles, furniture, and household appliances. At Interwoven we makes a distinction between functional apparel and soft goods, apparel being such a massive category that it is more useful to consider it separately – they are a completely different sector of our business.

While some soft goods are considered durable, the term is more closely associated with non-durable goods. Hard goods are, in comparison, closely associated with durable goods, which include products like tools, appliances, electronics, and jewelry. Hard goods are manufactured with ‘hard’ materials like plastic, wood, metal, stone, and composites. We specialize in incorporating hard materials into soft materials, to make them wearable and functional on the body.

How are soft goods manufactured?

As one can imagine given the size and diversity of the category, soft goods can be made with a wide range of manufacturing processes, and often multiple processes would be needed. These include ultrasonic or heat welding, sewing, knitting and weaving, mechanical fastening, injection molding, and bonding. These processes might join multiple soft materials or a combination of soft and hard materials.

Okay, but how are soft goods designed?

As the market is competitive, with many options available to the consumer, companies look to have soft goods custom-designed to stand out and appeal to their customer base. The design process can vary from one company to another in terms of the naming of the steps, the number of steps done in or out of house, and the time spent on any given step, but the structure tends to be some kind of iterative design cycle. There are often issues around fit and comfort that are specific to the soft goods product category. We can’t tell you how any given designer might do it, but we can walk you through how we do it.

Research

The research stage is about understanding people. The design process begins with determining the most important considerations for the desired product, which involves understanding what those considerations should be and why. This phase often involves observing and interviewing the intended audience about their needs and challenges as well as having conversations with the company about brand identity and project goals. It also includes determining the scope of the project, for example if the designer will be developing packaging and marketing materials as well as the product itself. Great designs empathize deeply with the people they are designed for and put them at the heart of the process.

Design

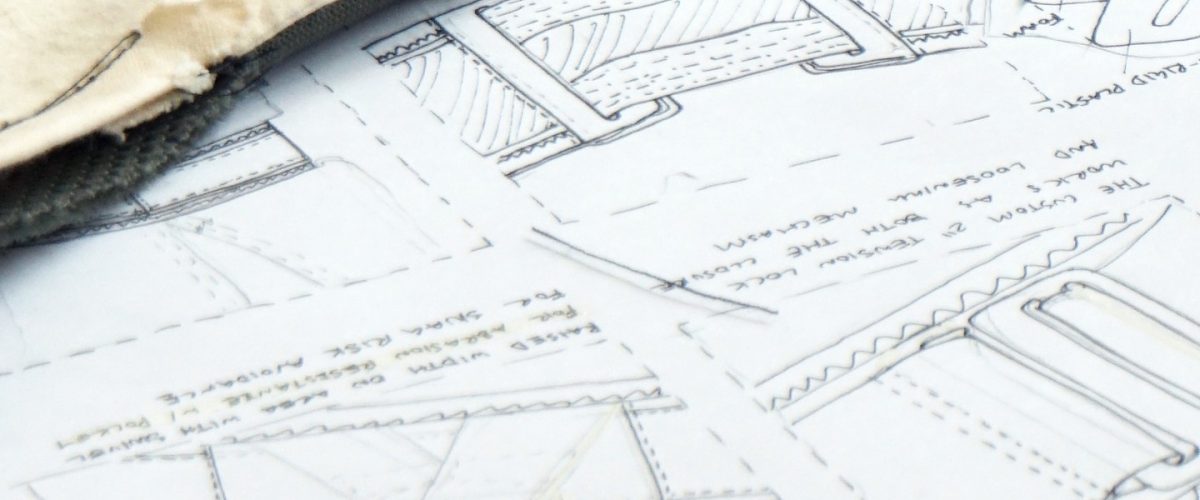

The design phase is about ideation and conceptualization. Ideation is the generation of ideas or concepts. A typical goal of this phase is to think creatively and generate a large quantity of ideas from which to draw. There are many strategies for both groups and individuals to use, including brainstorming tools and games, sketching, and model-making. Innovation and playfulness are powerful drivers for this stage. This phase is continually revisited to further explore and refine each prototype.

Prototype

A series of prototypes of the most promising ideas are created to further explore their validity. Each prototype is assessed by the designer and client together to determine what changes might be needed or desired, and a new iteration is prototyped. This process might take months or even years depending on the complexity of the product. Considerations for a textile product might include details like the specific type of material to be used. Should it be knitted or woven? How much stretch does it have, if any? Is it moisture-resistant, insulating? Does it need to meet any health and safety requirements? How much does it cost? Where can it be sourced? Likely several materials will need to be combined, each with their own list of properties required for the application and target price-point. How will they be joined, and what manufacturers are able to do the necessary processes? How will the desired form be constructed? Testing and assessment occur with each prototyping phase.

Manufacture & Launch

After multiple rounds of review a final prototype is approved, at which point the final technical drawings and material selections can be finalized. We create technical drawings and outline the material specifications so the order can go out to the manufacturer. We leverage the new product to capture industry market share.

So…what is soft goods design?

To return to the original question, soft goods design is a specific subcategory in the design industry that specializes in the design of products made with primarily but not exclusively non-rigid materials. It is a major category that makes up a significant part of the US consumer market and is driven by innovation, form, and aesthetics. The design cycle at our studio goes through four phases: Research, Design, Prototype, and Launch & Manufacture.

Interwoven Design is a design consultancy that is positioned at the intersection of soft goods and wearable technology, creating products that function with the body and offer comfort as well as the superb performance that arises through the innovative incorporation of rigid, often electronic and responsive elements. Sign up for our newsletter and follow us on Instagram and LinkedIn for design news, multi-media recommendations, and to learn more about product design and development!