Red Kap approached the Interwoven Design team to help develop an innovative new line of reflective Type O workwear garments. Key among the design problems to resolve was the durability of the reflective materials – an essential element for worker safety. Our process started with understanding how the garments are used, how they fit and function on the body, and their care and maintenance.

Project Firefly

What we did

- Ethnographic Research

- Materials Research

- Concept Development

- Garment Design

- Prototyping & Testing

Clients / Collaborators

Design Research

The Interwoven team did extensive research to analyze workers movements in Type O industries. Using industry training videos and site visit observations, the designers determined the most common body movements performed by workers in each job category where Type O safety garments are worn. Using this information, they analyzed how these garments are affected by the workplace through abrasion, stress and soiling. They also studied how the garments affect workers' comfort and mobility. Finally, the team visited industrial laundry facilities to gain insight into the care and maintenance of these garments.

Material Overview

Another area of inquiry was an extensive overview of reflective materials. Sourcing from manufacturers around the world, Interwoven compared each of the recommended use and care guidelines to what was observed in the industrial laundry, pin pointing discrepancies and determining opportunities for improvement. Armed with this information, we were able to design garments that enhance the user’s comfort while increasing the durability and lifespan of the garment.

Design Process

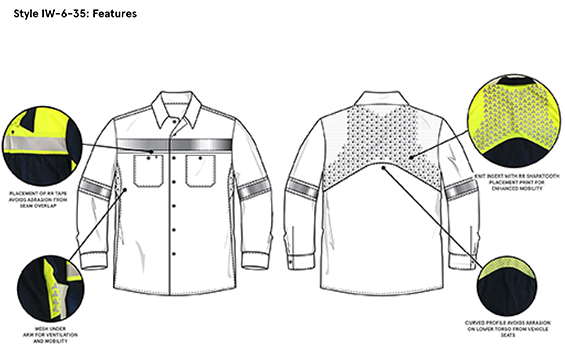

We explored design innovations through five design streams: abrasion avoidance, reflective patterning using over-glow, increased mobility and temperature regulation/ventilation. The results were 3 full garment concepts that combine elements from these design streams.

Using our innovative testing methodology to determine abrasion avoidance and range of motion, Interwoven was able to deliver garments with enhanced comfort, greater range of motion, improved durability and longer expected life cycle all with improved conspicuity and meeting or exceeding established safety guidelines.