Soft Goods, Seamless Performance: Designing for Movement in Entertainment

The Stakes of Entertainment Design

Designing soft goods for entertainment is a uniquely challenging discipline. Whether for stage, film, live events, or dance, these products must push the limits of movement, durability, and visual storytelling. Costumes, wearables, and accessories must look compelling under lights, but also support choreography, withstand repeated use, and integrate seamlessly. A garment that restricts motion or fails mid-performance doesn’t just interrupt the experience; it can compromise safety, storytelling, and the creative vision itself.

At Interwoven Design, we operate at this intersection of craft, performance, and technical problem-solving. Our team brings together expertise in soft goods, human movement, textiles, and engineering to create products that enhance performers’ abilities while preserving artistic integrity. From early movement studies to stage-tested prototypes, our work is grounded in creating pieces that feel natural to wear, perform reliably under stress, and advance creative expression.

In this article, we’ll explore what makes soft goods design for the entertainment industry distinct, how our approach supports both performers and creators, the opportunities emerging in this category, and case studies showcasing our work designing high-performance costumes.

Why Entertainment Design Is Unique

Designing for entertainment involves a set of conditions unlike any other category of soft goods development. Every decision must account for artistic intent, technical performance, performer safety, and the physical realities of movement.

Artistic Context

Costumes and performance wear must communicate character, story, and emotion at a glance. Designers navigate through color, silhouette, texture, and historical or stylistic accuracy. At the same time they ensure the garment supports the artistic direction of the production. A costume must function as both a tool for expression and a technical piece of equipment.

Physical Context

Performers push their bodies to extremes. Garments must allow full range of motion, distribute pressure evenly, manage heat, and remain comfortable over hours of rehearsal and performance. Fabrics that restrict, chafe, or overheat can hinder movement, increase fatigue, or lead to injury.

Technical Context

Modern entertainment frequently integrates technology; LEDs, sensors, animatronics, quick-change mechanisms, or modular components. These technologies must be embedded into costumes in ways that preserve flexibility, balance, and aesthetics while remaining easy to service backstage.

Together, these contexts shape a design discipline that is part engineering, part artistry, part biomechanics, requiring solutions that are expressive, durable, wearable, and safe.

Designing for Movement and Expression

At Interwoven Design, we view entertainment soft goods as extensions of the performer’s body and tools for storytelling. Our design process centers on an iterative, movement-driven approach that ensures each piece supports expressive freedom, technical performance, and long-term durability.

Prototyping is core to this philosophy. Early iterations are tested in rehearsals or motion studies, allowing designers to observe how garments behave during jumps, lifts, spins, or rapid transitions. We refine patterning, materials, seam placement, and support structures based on how performers actually move.

Comfort, breathability, and ergonomics are fundamental. Materials must balance stretch, drape, durability, and heat management. Every strap, panel, or internal structure is placed intentionally to reduce friction, support high motion, and maintain stability across repeated performances. When costumes incorporate technology, components must integrate seamlessly without compromising aesthetics or mobility.

Collaboration is also essential. We work with choreographers, costume designers, technical directors, and performers to ensure alignment between artistic vision and physical reality. This cross-disciplinary approach results in costumes and wearables that not only look extraordinary but perform flawlessly under demanding conditions.

The Challenge (and Opportunity) of Soft Goods in Entertainment

Soft goods for entertainment represent a rapidly evolving category, from high-tech performance to interactive costumes and modular pieces designed for quick changes or complex choreography. The opportunities are exciting, but the technical demands are significant.

Wearables must withstand extraordinary levels of physical stress. Unlike daily apparel, performance costumes experience constant stretching, repeated laundering, rapid changes, and sometimes rough backstage handling. Seams must hold, materials must last, and designs must maintain their appearance under stage lighting or camera scrutiny.

Technological integration adds further complexity. Whether incorporating electronics, sculptural elements, or mechanical activation, designers must ensure the costume remains balanced, lightweight, and flexible. A component that shifts or detaches mid-performance can jeopardize both safety and continuity.

These challenges, however, create room for innovation. Soft goods designers are uniquely equipped to bridge artistry and engineering. They develop costumes that feel weightless, move effortlessly, integrate technology invisibly, and elevate the creative vision. Our ability to unify soft materials with structural or technological components allows us to deliver reliable and expressive solutions.

Case Studies: Soft Goods for the Stage

Interwoven Design’s work in entertainment showcases how a human-centered soft goods approach can enhance artistry. It enables complex movement, and support demanding performance environments. To illustrate what we mean, here are two case studies illustrating how we’ve applied this expertise to ballet costume innovation.

Case Study 1: Fiber Optic Tutu for the Brooklyn Ballet

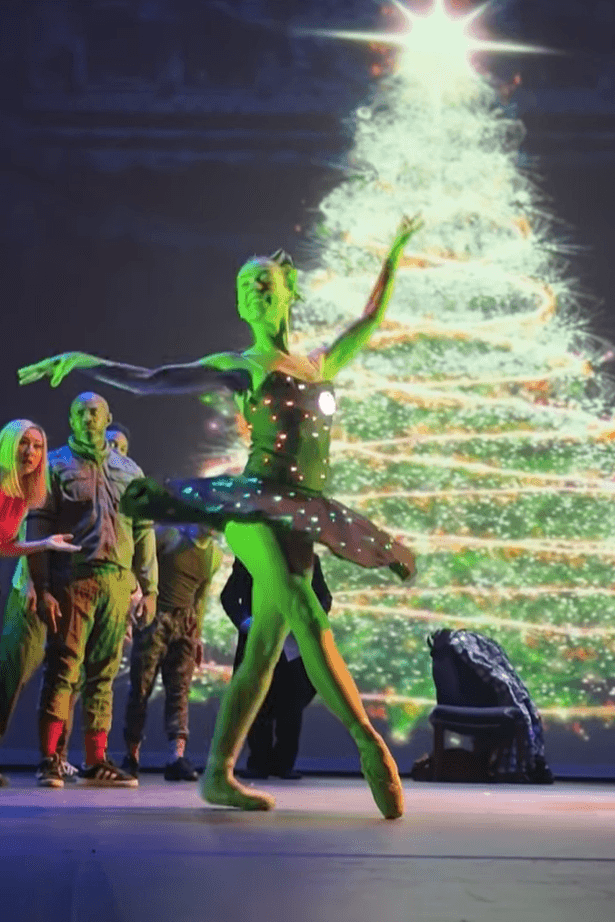

Interwoven Design partnered with the Brooklyn Ballet to bring a new dimension of storytelling to their production of The Brooklyn Nutcracker, creating a collection of illuminated costumes that merge classical craft with cutting-edge technology. The centerpiece of this collaboration, the Fiber Optic Tutu for the Waltz of the Flowers, unites traditional ballet couture with programmable light, transforming the stage into a living, glowing garden.

The Design Challenge

Ballet costumes must be expressive, lightweight, and durable, capable of withstanding continuous movement and intense performance demands. For this production, the creative direction introduced an additional layer of complexity. The challenge was to integrate lighting technology into garments that maintain the delicate elegance of a classical tutu.

The challenge was to create costumes that illuminated dynamically without compromising a dancer’s range of motion, stage presence, or safety. The light effects needed to be bright enough to read from the audience. They also needed to be subtle enough to blend with hand-dyed fabrics, layered tulle, and artisanal detailing inspired by botanicals.

Our Approach

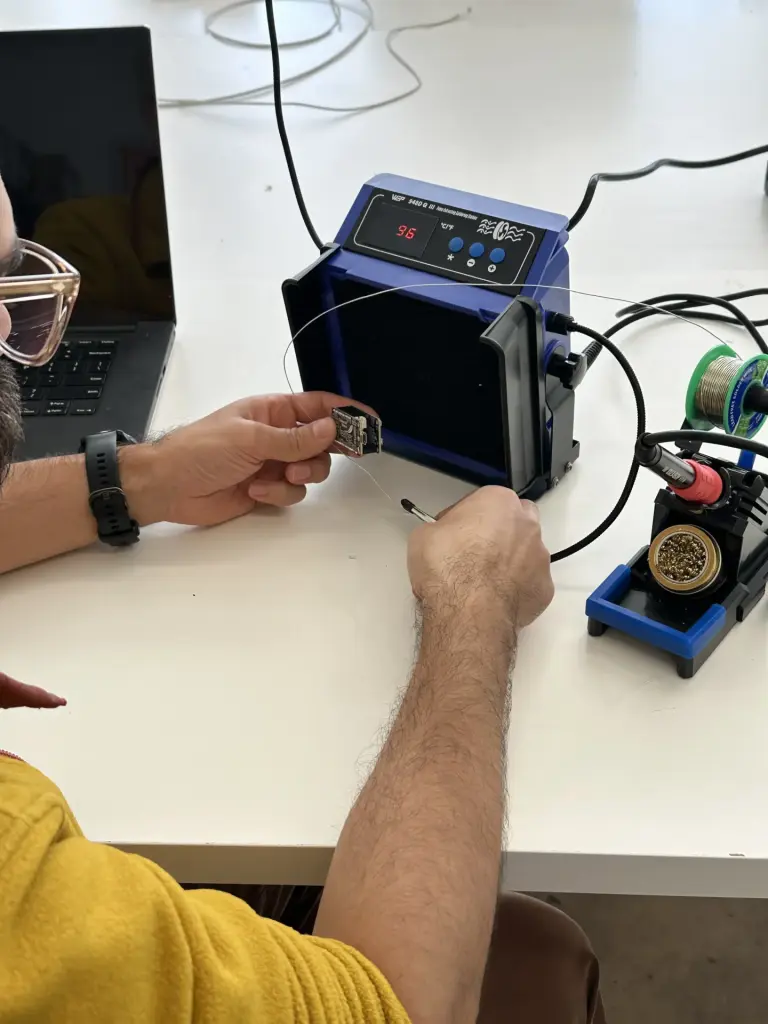

Interwoven Design explored the intersection of craft and circuitry, building the tutus using traditional multi-layered foundations reinforced with boning and custom-fit top plates. Then, an intricate network of fiber optic strands were hand-sewn onto the garment, bending and weaving with the dancer’s movement. When paired with high-intensity LED wands concealed at the lower back, the fiber optics created a shimmering glow across the costume.

To maintain the natural, garden-inspired palette of the ballet, the LED control boards were custom-programmed to precise hues of blue and green, ensuring that the illumination supported the choreography’s aesthetic rather than overpowering it. Additional costume elements for Garden Sprites and demi-soloists incorporated UV-reactive inks and screen-printed artwork that appeared only under ultraviolet stage lighting, creating a layered visual reveal. The Dew Drop character’s tutu featured laser-cut mylar florals and Swarovski crystals that refracted both ambient and programmed light, adding to the performance’s visual richness.

Behind the scenes, electronics were housed discreetly within the skirt structure. The housing protected the components while distributing weight in a way that preserved balance for the dancers. The integration of soft goods, illumination technology, and performance ergonomics was refined through iterative prototyping and collaboration with the ballet’s artistic and technical teams.

Impact

The Fiber Optic Tutu elevated The Brooklyn Nutcracker with a sense of wonder that blended seamlessly into the choreography. Onstage, the tutus appeared to bloom as dancers moved, bending light through the fibers to create glimmers, twinkles, and radiant washes that felt almost alive. The effect reinforced the narrative of a secret garden, bringing modern technology into harmony with classical ballet traditions.

For the performers, the costumes remained lightweight, wearable, and unobtrusive, supporting full movement while integrating a sophisticated lighting system. They delivered an unforgettable visual experience that captured the magic of nature, craft, and technology working in concert. This project highlights Interwoven Design’s ability to merge soft goods expertise with electronic integration. Hence, creating expressive, high-performance costumes that expand what is possible in live entertainment.

Case Study 2: Mechanical Doll Costume for The Brooklyn Nutcracker

More recently, for the 2025 season of The Brooklyn Nutcracker, Interwoven Design developed a new mechanical doll costume for the Waltz of the Flowers. This introduced a striking counterpoint to the fluidity and naturalism of the surrounding dancers. While the Flowers bloom and unfurl across the stage, the mechanical doll moves with intentional rigidity and precision. This created an aesthetic contrast reflected in the costume’s blend of structured hardware and soft textile elements.

The Design Challenge

Mechanical doll characters in The Nutcracker traditionally embody stiffness, rhythm, and clockwork-like gestures. For Brooklyn Ballet’s contemporary reinterpretation, the goal was to amplify this contrast. To create a costume that expressed mechanical articulation while still supporting the dancer’s mobility and performance.

The challenge centered on integrating rigid components in a way that conveyed a sculptural, almost automaton-like quality, without hindering choreography. Hardware needed to appear functional—even if only representational—while also being lightweight, safe, and capable of withstanding repeated performances. The soft elements, inspired by the surrounding cast, required balancing so that the mechanical doll felt visually connected while maintaining its personality.

Our Approach

Interwoven Design created the costume as a hybrid system, hard elements with soft materials that allowed for motion. Hard components—such as articulated panels, structured bodice, or mechanical-inspired detailing. We positioned them strategically to enhance the signature movements: sharp turns, precise steps, and sudden pauses.

Soft goods were incorporated to facilitate comfort and fluid transitions between poses, using textiles that complemented the production’s botanical palette without softening the character’s mechanical silhouette. The internal structure was designed to distribute weight evenly, so the dancer could perform full choreography while maintaining the illusion of rigidity.

We designed the hardware, embellishments, or frame-like structures to be secure yet flexible, allowing them to move subtly with the body. Throughout development, prototypes explored different ratios of soft-to-hard materials to achieve the right blend of theatrical expression, safety, and durability.

Impact

The resulting costume offered a visually arresting contrast within the Waltz of the Flowers, transforming the mechanical doll into a focal point of sculptural, rhythmic motion. The interplay of rigid and soft surfaces heightened the character’s stylized choreography, allowing the dancer to embody a precise, clockwork energy while remaining fully supported by the garment’s underlying ergonomic design.

For Brooklyn Ballet, the mechanical doll costume reinforced the production’s signature blend of tradition and innovation. Additionally, it showcased how contemporary design techniques, when thoughtfully integrated, can expand the vocabulary of classical performance.

Designing Confidence Into Performance

Entertainment design is about more than achieving visual impact, it is about building trust between performer, costume, and creative team. A well-designed garment supports movement effortlessly, withstands the rigors of performance, and reinforces the emotional world of the production. Whether crafting dynamic ballet costumes or integrating technology into stage wear, our mission is to blend artistic expression with technical excellence.

Through testing, movement-driven design, and respect for both performers and creative collaborators, we create intuitive, reliable, and empowering products. Our expertise in combining soft and structural elements ensures that each piece fulfills its artistic role and elevates the experience.

We invite choreographers, entertainment designers, and creative teams to partner with Interwoven Design to bring ambitious ideas to life. Designing for performance means designing for confidence, and that principle is central to everything we create.

Interwoven Design is a design consultancy that is positioned at the intersection of soft goods and wearable technology, creating products that function with the body and offer comfort as well as the superb performance that arises through the innovative incorporation of rigid, often electronic and responsive elements. Sign up for our newsletter and follow us on Instagram and LinkedIn to learn more about design and development!